A tiny particle can travel through concrete. It could save many lives

[ad_1]

Ernst Niederleithinger stands at the edge of an industrial laboratory in the south-western suburbs of Berlin.

It is nearing sunset, a week before the summer solstice. The room is illuminated from above by angled skylights reminiscent of a 19th-century painter’s studio. Around him in the gloom stand more than two dozen concrete monoliths, many half a metre thick, some close to two metres tall. A few weigh as much as 700kg. Drawn across their smooth, grey surfaces in pencil and ink are precisely measured grids, often grids within grids, at different scales. These inscriptions give the objects an archaeological feel, like exotic obelisks waiting to be interpreted.

Gazing at the monoliths, Niederleithinger knows he can do the impossible: he can peer inside solid concrete, examining the depths of even the densest material. Although the massive shapes lurking inside are nothing more than oversized blocks, Niederleithinger cautions against any notion of simplicity. “Concrete,” he says, “is very complicated.”

For the past 21 years, Niederleithinger has worked at Germany’s Bundesanstalt für Materialforschung und -prüfung, the Federal Institute for Materials Research and Testing, or BAM as it is known. BAM was founded in Berlin in 1871, tasked with assessing the “strength of iron and steel”. Its remit has since broadened considerably. Today, with 1,600 employees, the institute helps to set rigorous national safety standards by testing different materials — concrete, but also composites, nanomaterials, microplastics, lithium-ion batteries, even nuclear waste containers — before they are adopted by German industry. “Sicherheit macht Märkte” is BAM’s motto: safety creates markets.

Concrete is one of the most widely used materials on Earth. Every year, more than 10bn tonnes of it are produced; 70 per cent of humanity lives in a structure made from reinforced concrete; and, by 2030, global concrete industry revenues will reach nearly $1tn, according to an Allied Market Research estimate.

Concrete has become both a technical and moral fixation for Niederleithinger. Over time, concrete can crack and decay. Cables and metal embedded in the material can corrode or snap, leading to failure. Bad concrete puts entire buildings and transportation systems, not to mention countless lives, at risk. Drilling test holes in every bridge span, foundation wall, auditorium roof and dam to determine the health of those structures, however, is not only economically impossible; it could damage the very things engineers want to study.

When a residential high-rise collapsed in Surfside, Florida, in June 2021, killing nearly 100 people, structural experts pored over the ruins. Close examination suggested that some of the building’s concrete pillars, which shattered in the collapse, appeared to contain insufficient rebar, the steel used inside as skeletal support. If construction crews had skimped on this vital reinforcement, that might help explain why the structure collapsed: it had been overloaded for decades.

But it also might suggest that other buildings, not just in Florida but around the world, face a similar risk. Had there been a way to see inside the concrete to inspect the pillars without damaging them, perhaps catastrophe could have been avoided.

As Niederleithinger walks from one monolith to the next, he pauses over particularly interesting pieces, like a curator inspecting a Brutalist sculpture garden. “Our main aim is to find methods to look into concrete,” he says, “to be sure that everything is as planned, that all the metal rebar and whatever else that is supposed to be there is in the right place.” At one point, he grabs an ultrasound machine and presses it up against the surface of a concrete mass. A cluster of red and green shapes appears on the device’s screen. Rebar.

Through non-destructive means, including X-rays, ultrasound and radar, BAM’s engineers have a wide range of technical options at their disposal to peer into objects made of concrete, but also steel, wood or stone, in the hunt for signs of fatigue, rust and other forms of corrosion.

But each of those tools has its limitations. Radar cannot penetrate deeper than about two metres, meaning that thick walls or pipelines and other structures buried below a certain depth cannot be imaged. Ultrasound can be noisy, prone to echoes and self-interference with dense materials, producing incoherent images.

X-rays are almost ideal, offering crisply detailed images, produced quickly, but they have one obvious flaw: they are a form of radiation and pose immediate health risks to anyone exposed to them. X-raying a large structure or piece of infrastructure in the middle of a city can require evacuating the entire area, not to mention copious amounts of paperwork as researchers apply for the necessary safety permits.

Niederleithinger pauses by a wall of heavy shelves holding multiple slabs of concrete. In one of them, ductwork coming out of the side was visible. “If you could have some kind of detecting system that doesn’t use X-rays but uses natural cosmic rays, which are here anyway,” he says, “that, of course, would be great.” Which is exactly what Niederleithinger and his colleagues at BAM have their eyes set on: a new imaging technology that can safely and cheaply see through almost any structure on Earth using particles from space.

This cosmic tool promises to revolutionise construction technology, accelerate everyday building maintenance and potentially save millions of lives. If Niederleithinger is right, the muon revolution is only two or three years away.

The power flickers on and off in Raffaello D’Alessandro’s office, shutting down his computers and air-conditioning. It is early summer in Italy and a heatwave is passing through. D’Alessandro teaches physics at the University of Florence. He performed the bulk of his postgraduate research at Cern in Switzerland, including experiments with the facility’s Large Hadron Collider, a 27km-long underground particle accelerator straddling the border with France. Next to his desk, tucked away near the window as if to keep it cool, is a muon detector called Muon Imaging for Mining and Archaeology, or MIMA.

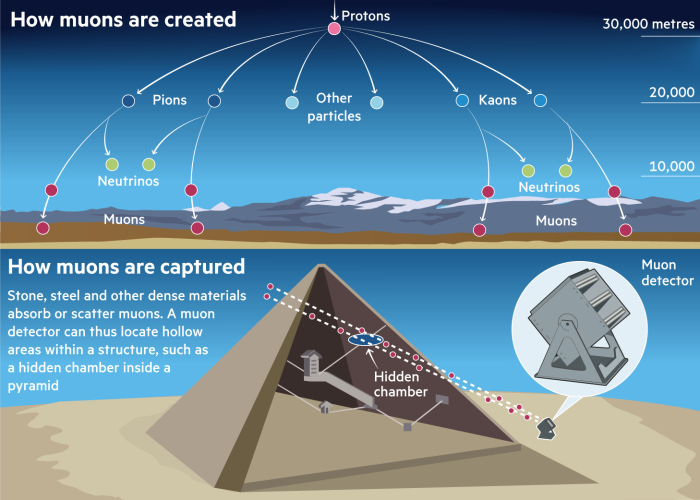

Muons are shortlived, highly energetic particles generated in the Earth’s upper atmosphere by collisions with cosmic rays. Though they exist for mere microseconds, muons travel at nearly the speed of light and are able to penetrate deep into the Earth’s surface. They pass through cathedrals and dams, motorways and hospitals, through steel, stone and concrete.

Proof of their existence was first demonstrated in the 1930s by a series of experiments that showed this previously unknown particle — roughly 200 times heavier than an electron — was one of the universe’s fundamental ingredients, cousin to the better-known quarks and neutrinos. Today, we know that an estimated 600 muons pass through our bodies every minute of every day and night.

Although muons penetrate matter with ease, their ability to pass through an object or structure decreases with a material’s density. Muons en route through a large building or mountain will be subtly but measurably filtered out by thick masonry or heavy ore, with the effect that more muons will travel through zones of emptiness — the first clue that a room, cave or magma chamber must exist somewhere inside.

Similarly, muons passing through a material such as concrete will be blocked or scattered just enough by the steel rebar, which can be seven times denser than concrete, to indicate that something — an object or anomaly — must lurk within.

Using complicated mathematics and modelling software, physicists can then calculate — and thus visualise — what those muons have passed through. In other words, muons can be used to make images. It is called muography: one part comic-book superpower, one part cosmic photography.

MIMA is a ruggedised metal box, a cube of roughly 50cm, mounted on an adjustable stand. Although its three trays house sensitive muon-detecting electronics — specifically, scintillators and photon detectors borrowed from the nuclear industry — the device could easily be mistaken for an office microwave.

For a machine that can see the invisible, it uses surprisingly little power, about the same as a standard lightbulb. This means the device can be run for several days from a single battery pack and can even be solar-powered. Producing muographic images is also deceptively simple: just turn on the detector, go back to your office and wait as the data trickle in.

“The problem,” D’Alessandro says, “is waiting for enough muons to arrive.” Developing muon imagery takes time. If, on average, only one muon per minute passes through an area the size of your palm, then it can take many days, even weeks, to develop a coherent, large-scale image of a building. Unfortunately, this aspect of muography cannot be sped up or improved. “That’s a physics limitation,” he explains, “not a technology limitation.”

The resulting images look a bit like high-contrast photocopies, their ghostly grey tones resembling early daguerreotypes, the precursor to modern photography. But when used at the scale of buildings, muography has centimetre-scale resolution, which means that pieces of rebar, as well as signs of corrosion or damage, are easily visible. With ongoing advances in software and image-processing algorithms, that resolution will probably be down to millimetres within a few years.

As the “archaeology” in its name implies, MIMA has been used successfully in an array of cases that go well beyond imaging concrete. D’Alessandro has used MIMA to measure ore bodies in underground mines, to help archaeologists survey previously unmapped Etruscan tombs and to keep tabs on the internal structure of Italy’s notorious Mount Vesuvius.

If Vesuvius erupts again with anything like the power of the explosion that destroyed Pompeii in AD79, the entire city of Naples could be razed. By detecting changes in the volcano’s magma chambers, indicating an imminent eruption, muography could function as an early-warning system, saving millions of lives.

Muon detectors have, in fact, been used for architectural imaging since the 1960s. Muography’s big break came at the end of that decade, when University of California physicist Luis W Alvarez installed a muon detector beneath the Pyramid of Khafre in Egypt. Alvarez’s goal was to locate a hypothetical unknown chamber believed to exist somewhere deep inside the structure. Although Alvarez’s work showed that no such room existed, muography was again put to use, in 2017, when researchers discovered an unexplained void — possibly a royal burial chamber — hidden in the nearby Pyramid of Khufu.

Because muons are especially good at revealing voids, muography has also been used in the Yucatán rainforest of Mexico. There, physicists from the Maya Muon Tomography Group at the University of Texas at Austin scanned remote, overgrown landforms, revealing that what appeared to be hills were, in fact, buildings — ancient Mayan temples with unexplored rooms and chambers inside.

MIMA might yet find its most consequential use, however, helping to analyse, and thus preserve, one of the world’s most celebrated works of architecture. In the centre of Florence, looming over the restaurants, boutiques and narrow streets around it, is a cathedral. Its surface is a spectacular patchwork of contrasting marble. Marine greens and rose pinks share space with paperwhite stone blocks; ornately carved statues and geometric patterns adorn every few feet.

Atop the otherworldly extravagance of the cathedral walls is a cupola, or dome, designed by architect Filippo Brunelleschi in the 15th century. A religious and gravitational marvel, Brunelleschi’s dome and its related structural supports contain an estimated 100,000 tonnes of rock. Parts of the dome’s inner shell are nearly two metres thick.

One of the illusions of architecture is that buildings are immobile. In fact, they are dynamic systems, always on the move. Almost immediately upon construction, cracks appeared — some large, none well-explained — in the walls of the nave.

The cupola, made of countless individual blocks of stone, is constantly responding to gravitational settling, seasonal temperature change, earthquakes and the effects of rain and snow. These endless adjustments have been compared to plate tectonics: rock masses jostling against one another in a centuries-long sway.

All of this motion may or may not pose an existential threat to the cathedral. No one is sure what the long-term effects will be. Some engineers have suggested that the cracks function more like expansion joints, as measurements have revealed that they open and close with the seasons. Rather than suggesting the imminent collapse of the cupola, in other words, the cracks might be acting as pressure-release valves, helping to regulate long-term settling of the building.

Yet a definitive explanation of what caused the cracks in the first place remains elusive. For nearly 400 years, architects, mathematicians, and engineers — even a Jesuit astronomer — have studied them. Hypotheses have ranged from long-term water damage related to an underground stream to “localised horizontal tensile stresses exceeding the strength of the masonry”, as the authors Giovanni Fanelli and Michele Fanelli write in their history of the dome, Brunelleschi’s Cupola.

No matter what the cause, 21st-century engineers hoping to reinforce the cupola and protect it from future collapse face an unusually frustrating problem. Part of what gives the dome its enduring mystery, its architectural awe, is that Brunelleschi left behind no construction documents, not even a description of how the dome was assembled. This means that no one today understands exactly how it was put together or how to fix it.

What engineers and historians do know is that the cracks have been growing wider at a rate of 7mm per century. To keep tabs on them, sensors known as “deformeters” have been installed, measuring the cracks’ growth to within an error of 0.02mm. Thermometers, humidity gauges and level-checking instruments dot the church interior. So many technical studies were under way by the 1980s that The New York Times suggested the dome had “a solid claim as the world’s most carefully monitored structure”.

D’Alessandro is not the first to have spotted the potential of muography to save the cupola. Elena Guardincerri has a PhD from the University of Genoa. That city was the site of another infamous infrastructural collapse in August 2018, when a motorway bridge failed, killing 43 people and destroying much of the neighbourhood below. Guardincerri works at the Los Alamos National Laboratory (LANL) in New Mexico. During a conference at LANL in 2013, one of her colleagues, Cas Milner, wondered aloud whether muons could be used to image Florence’s cathedral, helping with efforts at its long-term preservation.

Guardincerri’s initial view of muons, she said, not without irony, was that they were a distraction from her real research. At the time, she was studying neutrinos, subatomic particles that can be mistaken for muons (and vice versa). Muons made her already complicated work much harder. But eventually she came to see their potential, and she fabricated a mock-up of the cupola’s masonry shell in her New Mexico lab.

She began performing proof-of-concept muographic surveys on it, showing that the same particles she once found so annoying could be used for architectural imaging. When funding for this particular project was discontinued, the door was left open for D’Alessandro and his colleagues to pursue their research.

Armed with MIMA, D’Alessandro and his team have one specific goal, a target that will reveal whether the church already has internal reinforcements inside the masonry. During the dome’s construction, Brunelleschi ordered and received a shipment of iron believed to have been used to fashion a titanic chain that was then strung inside the dome’s inner shell, holding it in place like a necklace. Yet no such chain has ever been found. It is probably in there somewhere, but where? X-rays pose too much of a danger to visitors and residents alike. Radar, meanwhile, cannot penetrate the dome’s two-metre-thick walls.

Part of the appeal of using MIMA inside the church is that it will be so unobtrusive: a small metal box operating in near-silence, emitting no light, reverently awaiting particles from above. D’Alessandro and his team will need to move the detector every two or three weeks to a new spot in the church, then use software to rectify the resulting data sets. From that, images will emerge, pulling cosmic shadows into focus, including, they hope, evidence for or against the existence of a chain deep inside the rock.

The use of a tool originally intended for mining and volcanology seems strangely appropriate when one climbs through the vast interior of the cathedral. A series of tight corridors, dimly lit ramps, and steep stairways gradually bring visitors up into Brunelleschi’s dome. At times, the building can feel more like a mountain than a work of architecture, its masonry so substantial, the height of its dome so extreme, that those with vertigo are better off not knowing they are hundreds of feet above the church altar below.

Of course, the sweltering heat that made the power in D’Alessandro’s office fail could also be felt through the walls of the cathedral. Heatwaves like the one that was roasting Florence this summer will only become more common with climate change. This will considerably worsen each season’s thermal effect on Brunelleschi’s dome. Concrete and masonry structures all over the world might find themselves experiencing cracks and fracturing in the coming decades, giving muography’s pending uptake unfortunate urgency. But also an expanding marketplace.

The entirety of BAM’s Division 8.2 traces much of its current mission to an architectural tragedy that could probably have been avoided using muography. At the time of its construction in the late 1950s, Berlin’s Kongresshalle was a rare example of a prestressed concrete shell. A gift to West Germany from the US, the hall took the form of a hyperbolic paraboloid — picture a Pringles crisp. Part of the building’s structural flair was that its roof was supported by long steel cables strung through the concrete itself, allowing the roof to cantilever, even with its enormous weight, over the open lobby below.

For 23 years, the hall stood without incident. Then, in May 1980, its concrete roof partially collapsed, killing a journalist and injuring several visitors. Although later explanations for why the roof failed included many root causes, one detail stands out: the installation of a reflecting pond outside the hall was more fateful than anyone could have realised. Humidity from the pond penetrated deep into the concrete on that side of the building, corroding and then snapping the steel cables one by one. Because the cables were inside the concrete, however, no one could see that they had broken.

A full-colour photograph of the hall now hangs on a wall inside Division 8.2, a constant reminder to BAM employees of what they’re really working for. (Subsequently reinforced, the Kongresshalle still stands, since renamed as the Haus der Kulturen der Welt, an arts and performance venue.)

Niederleithinger and his colleagues at BAM are working on testing and certifying muography so that it can be approved for commercial use. In essence, their challenge is to help turn a high-energy physics experiment into a product. Without a muon detector of their own, however, BAM has been sending its concrete monoliths — Niederleithinger describes them as “reference objects” — to the University of Glasgow in Scotland. Because of their extreme weight, the blocks are transported by truck and ship. They are then imaged in Glasgow and, using the grids marked on their surfaces, any intrusions, foreign objects or flaws inside the block are noted.

Before muography can become more common, Niederleithinger admits, it must be proven irrefutably to be both accurate and dependable. He estimates it will take another two or three years for the evidence to accumulate and for standards to be drafted and applied.

Early next year, Niederleithinger will be relocating to Glasgow for three months to work intensively on muon testing and certification. He will be joining one of his key collaborators, David Mahon, a research fellow in the school of physics and astronomy at the University of Glasgow and business development manager of a private muographic-imaging company called Lynkeos Technology.

Named after one of the Argonauts from Greek myth, a guide who could see through objects, including the surface of the Earth, Lynkeos is based in Glasgow’s West End. For now, its biggest contracts are with the UK nuclear industry, which has hired Lynkeos to scan radioactive waste containers at the Sellafield decommissioned reactor site using muons.

For Mahon, muography presents a classic case of the challenges in bringing an unfamiliar technology to market. “Muography can play a significant role in improving lots of different industries,” he says. “But the issue is adoption, getting industry to take a chance on this space-age technology.”

It takes longer than an X-ray, he agrees, but it doesn’t require the lengthy permitting process and thus might save time in the end. It uses almost no electricity. And, he argues, the beauty of muography lies in its hands-off nature: you just securely install the device and walk away.

“With the nuclear industry in the UK,” he says, “we might sell one or two systems every few years, but it’s not a business model that people want to invest in”. The result is that detectors are expensive: even a small one such as MIMA, which would normally cost at least €50,000, has doubled in price in recent months to €100,000, as a result of the global chip shortage and because some components are from companies affected by sanctions following Russia’s invasion of Ukraine.

“It’s a bit chicken-and-egg,” Mahon concedes. “You need the market to be big, so that the components are cheap, but you don’t get the volume in the market if you’ve got really expensive systems.”

What’s more, current muon detectors lack flexibility. What muography needs, Mahon says, is not just investors but designers: people who can design flexible, modular frames and structures to ensure the equipment can fit in irregular spaces. It is one thing to put a clunky detector such as MIMA on the floor of a mine and start collecting cosmic particles, it is another entirely to squeeze a functioning muon detector into the cramped vaults of a cathedral, an underground rail tunnel or a congested crawl space beneath a bridge.

To this end, Mahon is working to develop 3D-printed armatures, inside of which muon-detecting sensors can be woven. Rather than purchase new components for each detector, these sensitive electronics can be reused in different forms. This means that even the most complicated, unique architectural spaces can be catered for, with bespoke 3D-printed shells for infinite future detector geometries.

“It doesn’t reduce the cost of individual components, but it means we don’t need to keep a massive stockpile of expensive parts for single-use imaging campaigns,” Mahon explains. “It reduces the time it takes for us to assemble new detectors and just makes it a bit more flexible.”

Like Niederleithinger, Mahon is bullish about muography’s future markets. Muons are already used for border-security inspections, he points out, including by a San Diego-based company called Decision Sciences, which uses a larger version of the muon detector system developed at LANL as part of a vehicle inspection station.

Trucks entering the US from Mexico can be selected for additional scanning. Drivers are asked to pull up into a machine that looks vaguely like a car wash, with a muon-detecting canopy and muon-detecting floor plate. Muons raining down through the truck can be imaged to reveal the presence of ultra-dense metals, such as uranium or plutonium, that could be smuggled into the country to build a dirty bomb. Similar muon inspection infrastructure is operational in a handful of global shipping ports, including Singapore, Boston and the Bahamas.

Muon detectors have also been proposed as a potential method of detecting illegal tunnels under the US-Mexico border. By excavating a sequence of deep boreholes along the border and placing a muon detector in each one, law-enforcement agencies might be able to capture the gradual excavation of an empty space from the ground above. With BAM, Niederleithinger has begun working with Germany’s autobahn authorities to image bridges, looking for damage or corrosion, in the process demonstrating that muography will work outside the controlled environment of a laboratory.

Where Mahon and Niederleithinger also agree is that muography can show architects and engineers better ways to design structures in the first place. “The more data we have, the better we can make things in the future,” Mahon explains, citing the examples of better grouting and seals for rebar and prestressed concrete. For Niederleithinger, muography could also improve maintenance of existing structures, cutting down on the use of concrete and thus the greenhouse gas emissions associated with its production.

“What’s the benefit for our economy?” he asks. In his Berlin lab, his colleagues have long since gone home, leaving him alone amid the gridded slabs and inscribed obelisks of BAM. “Don’t dismantle the old bridges, but inspect them, strengthen them, repair them, so that we can use them for another couple of decades,” he says. “The best thing to do is to take care of existing structures so that they don’t have to be replaced. This will save a lot of money for the taxpayer.”

Muography may be the future, but it can appear less than futuristic. “I have to warn you,” Mahon says. “A muon inspection is not an exciting thing. Nothing happens. There are no flashing lights. It’s just black boxes with something in the middle.” But if black boxes installed around cities, beneath bridges, inside basements, even under pyramids and cathedrals, can help protect us from structural failure, then being boring seems an acceptable price to pay.

Geoff Manaugh is a US-based architecture and technology writer. Research for this article was generously supported by a grant from the Graham Foundation for Advanced Studies in the Fine Arts

The MIMA muon detector illustrations were created by Lorenzo Bonechi and Diletta Borselli. Research was funded by INFN-Florence and the University of Florence

Follow @FTMag on Twitter to find out about our latest stories first

[ad_2]

Source link